Overview

Kit assembly refers to the process of transferring quantities from a kit component to a kit parent while grouping them until the bundle is fully assembled. Kit Assembly Work Orders, on the other hand, serve as comprehensive guidelines for the assembly process, providing clear “how-to” instructions to your warehouse staff. These work orders include a detailed list of the components required to create the kit and can be easily printed to PDF/Excel format for seamless distribution.

Creating Kit Assembly Work Orders is only possible through the Skustack Admin, while managing existing work orders can be done through the Skustack app.

Kit Assembly Work Orders

The Work Orders module is located within Skustack’s Work Orders tab and allows you to search for open work orders, pick items, and assemble kits before shipping them to FBA.

Search Work Orders

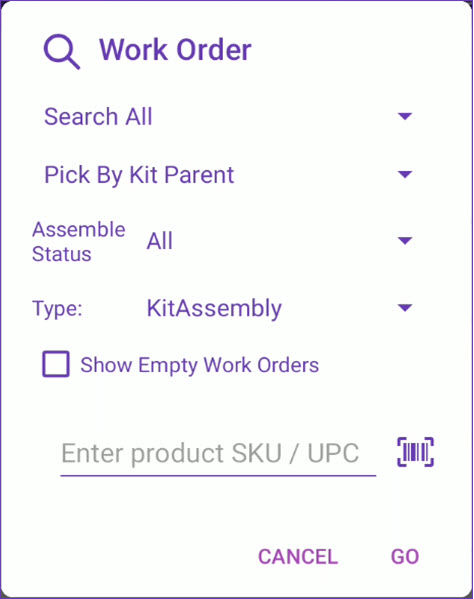

You can search for Work Orders in one of three modes:

- Search By Work Order ID – Opens a single Work Order using the internal Sellercloud ID.

- Search By Title – Opens a single Work Order using its title.

- Search All – Searches for all Work Orders. You can filter by Type – Kit Assembly and narrow down the search results even further by searching for a specific SKU/UPC or Assembly Status.

- Pick by

- Kit Parent or Kit Component.

- Status

- Defaults to all. You can choose from one of the available statuses:

- All

- Zero Assembled

- Partial Assembled

- Zero or Partial Assembled

- Fully Assembled

- Type

- Defaults to all. Select Kit Assembly.

- SKU/UPC

- A convenient option to search for all work orders associated with a particular product.

Manage Work Orders

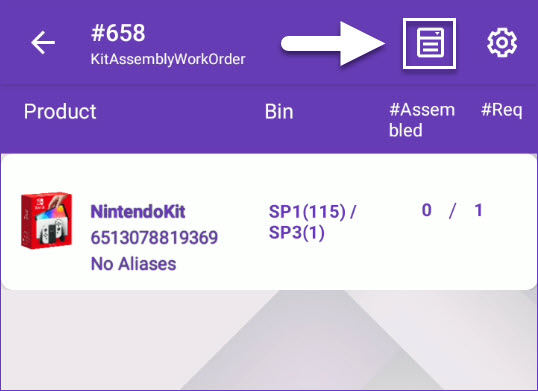

To work on an open Kit Assembly request, navigate to the desired Work Order:

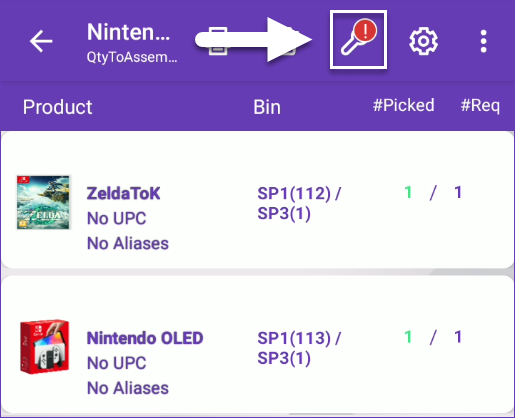

- In the top right corner of the task, you’ll find an icon that allows you to Select Product Identifiers to Display – tap and choose the product identifiers to be displayed in the work order:

- UPC

- Aliases

- Product Name

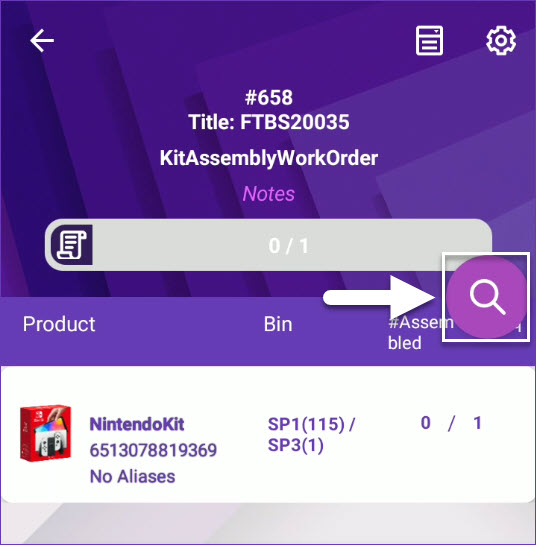

- Swipe the header down to see the total number of items and view/add notes. Tap on the magnifying glass to search for specific products in your work order.

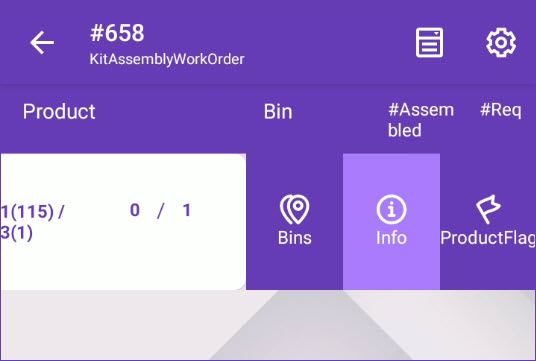

- Swipe left on the items to reveal shortcuts to other actions:

- Bins – Tap the icon to see all bins where the product is stored (bins will show only if you’re logged into a bin-enabled warehouse).

- Info – Tap to be directed to the Product Info module.

- Product Flag – Tap on this icon to add a Product Flag.

- If you are picking by kit parent, select the kit parent on the screen. The components of that kit will load. If you are picking by component, all components will load automatically.

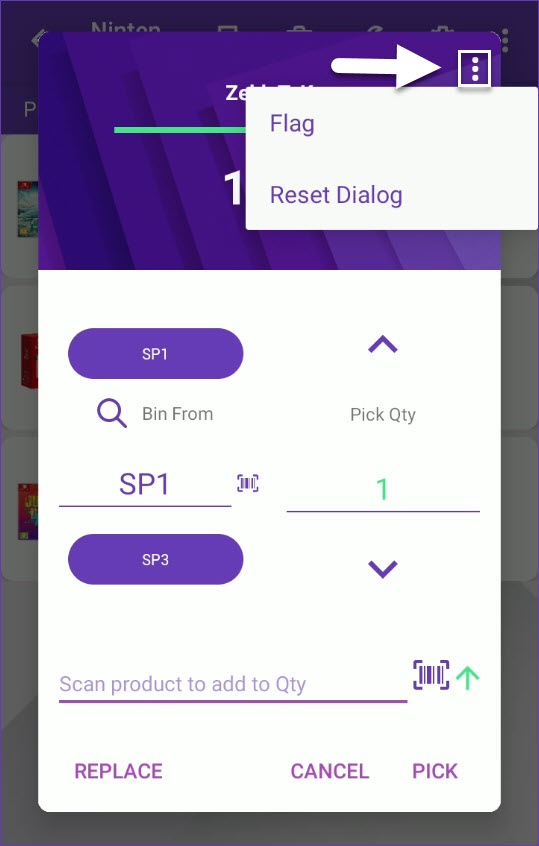

- Scan the ProductID/UPC, or select the item on the screen. The product will open.

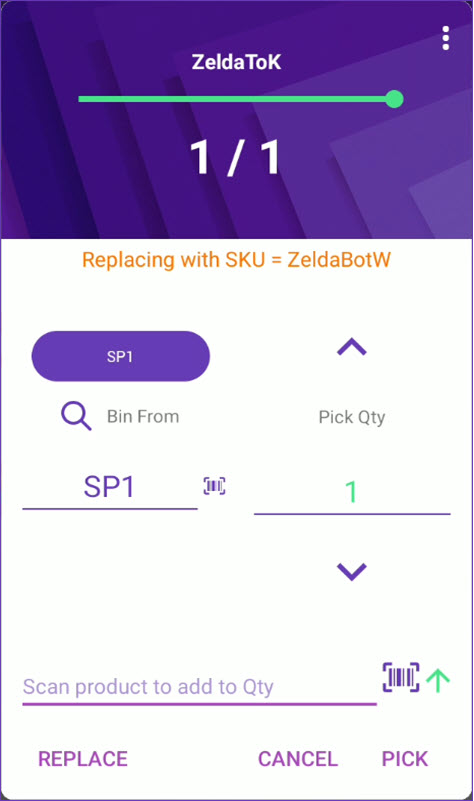

- Scan/enter a bin, or select one of the suggested bins. The suggestion is based on the following factors:

- The bin is sellable.

- The bin type is Normal or Temp.

- Primary bins will always be suggested first.

- The bin with the most or least quantity will be suggested based on the client setting PickList Bin suggestion sort qty by ASC Order.

- Scan units to add to the picked qty or adjust the number manually. To auto-populate the total quantity available for the scanned product in that bin, enable Skustack’s Warehouse Management setting Auto populate progress quantity when bin is selected.

- Tap on the three dots menu in the upper right-hand corner to:

- Flag – Use this option to Flag the item and indicate specific concerns.

- Reset Dialog – Use this option to remove selected data from the picking dialog.

- If the component quantity is depleted, you can tap on Replace and choose a replacement product.

- If the Lot Number workflow is enabled for your company and the product is set as expirable you must select a Lot Number before being able to pick it.

- Tap Pick.

- The picked quantity will display next to the Pick Qty (e.g. 1/1) and the components will be transferred to the Assembly bin.

- When all components are picked, tap the Tool icon at the top right to assemble the kit.

- A new activity dialog with a list of the components will open. Scan items to assemble them.

- If any of the components are serialized, you will need to assemble one kit at a time.

- Once all the components are scanned, the assembly will begin and you will be prompted to put away the kit.

- Choose a bin to put your kit(s) away into or use the TempBin generated by the system. The components will be transferred out of the Assembly bin and into your chosen destination bin.

- You will be prompted to print labels for your kit. Choose from the following available options:

- Print kit parent serials

- Print both (labels and serials)

- Print kit product labels

If the Auto Print Kit Labels Warehouse Management setting is enabled, both labels and serials will print out automatically. - The kit is now assembled in your destination bin.

Related Settings

| SETTING | DESCRIPTION |

| Validate serial globally | Client setting. Enables serial number validation in Skustack. Learn more about serial number validation and relevant client settings here. |

| Require Component Serial Scan If Necessary | Skustack’s Warehouse Management setting. When enabled, will force the user to scan serials for components that are set to require serial scan. |

| Scan To Assemble | Skustack’s Warehouse Management setting. When enabled, will force the user to scan kit components to assemble them. |

| Auto Print Kit Labels | Skustack’s Warehouse Management setting. When enabled, kit labels will be printed automatically upon assembly. |

| Auto Close After Fully Assembled | Skustack’s Warehouse Management setting. When enabled, the work order status will be automatically updated to Completed. |

| Allow Unlock Work Order | Skustack’s Warehouse Management setting. When enabled, this setting allows you to edit/add products to Work Orders. |

| Auto populate progress quantity when bin is selected | Skustack’s Warehouse Management setting. When a bin is selected, the Pick Qty field will automatically be set to the total quantity available in that bin, up to the quantity required. |

Kit Assembly Work Orders

The Skustack Admin portal lets you easily create new work orders, as well as manage existing ones.

Create Work Orders

To create a new Kit Assembly work order:

- Navigate to the Skustack Admin portal at https://xx.skustack.com (replace “xx” with your server ID or team name).

- Enter your login credentials.

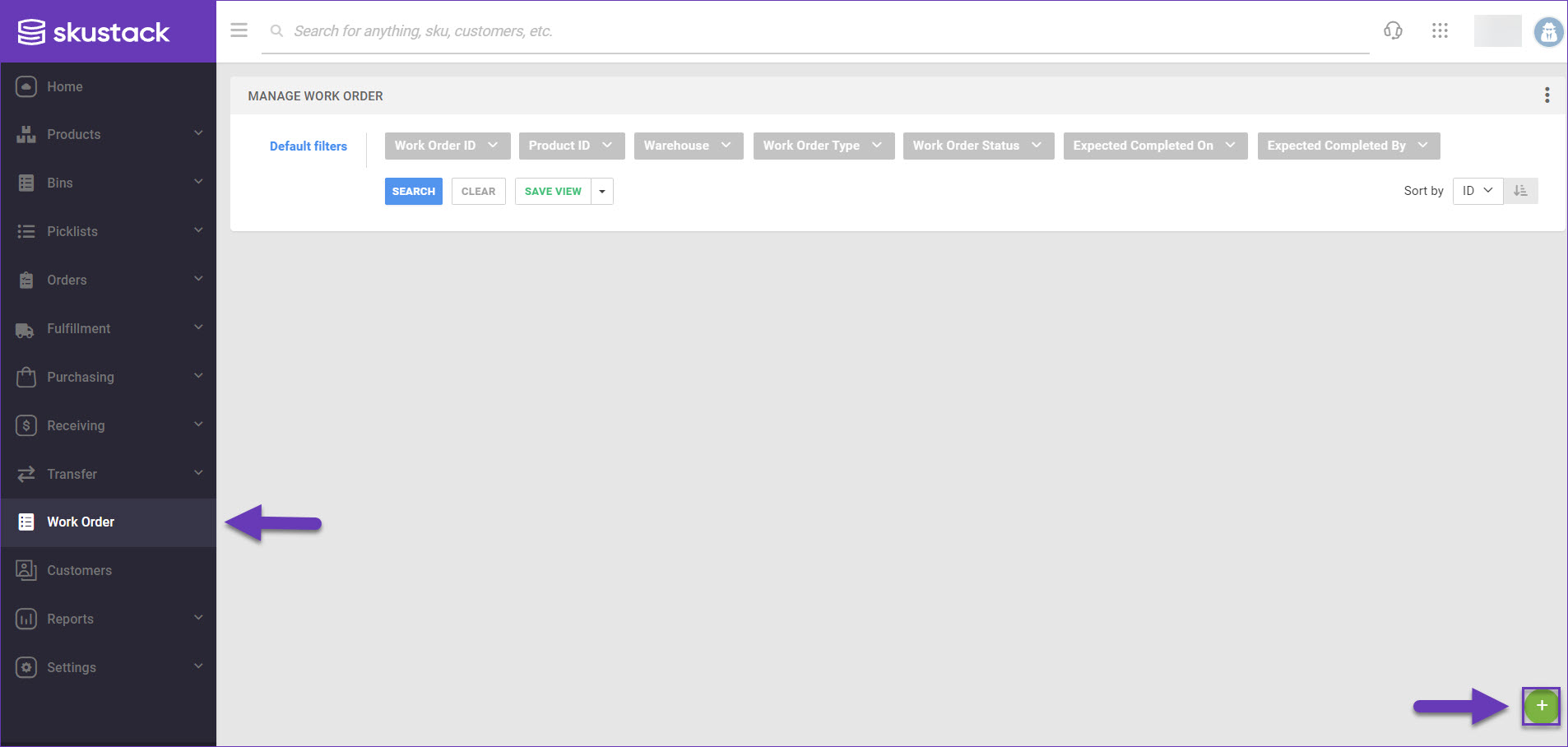

- On the left, select Work Order and click on the + icon.

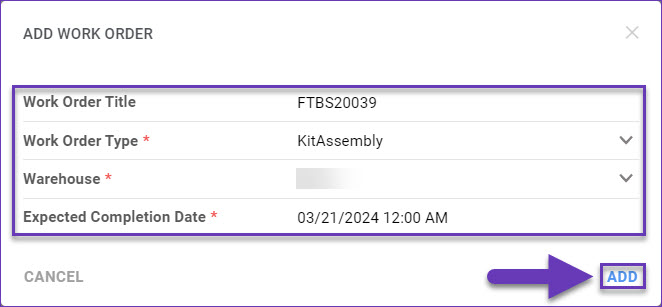

- Enter the following details:

- Work Order Title

- Work Order Type – KitAssembly

- Warehouse

- Expected Completion Date

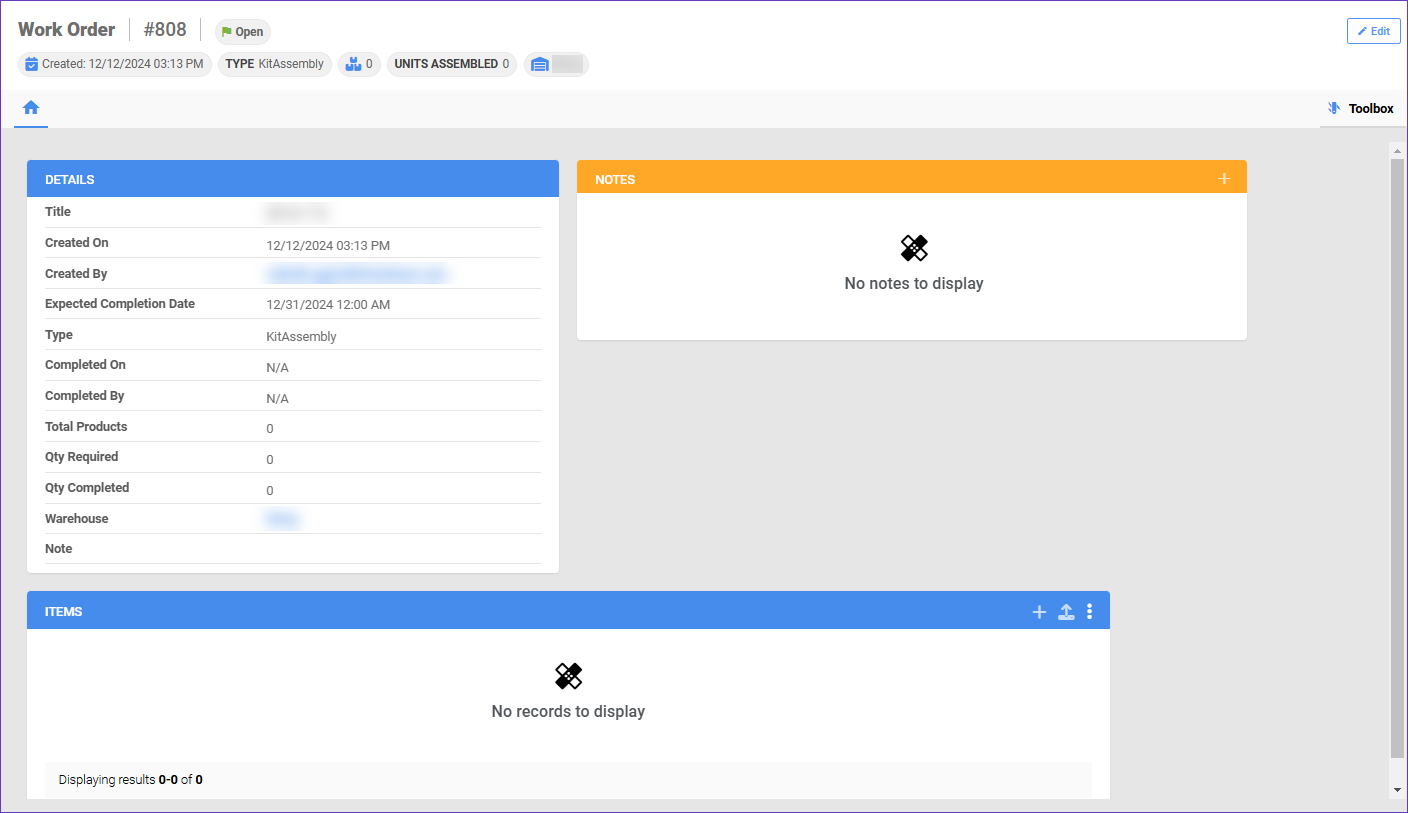

- Click Add and the new Kit Assembly Work Order will load on your screen.

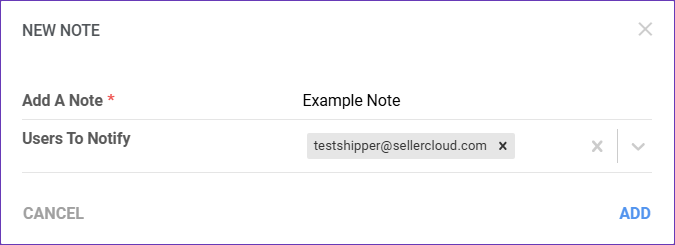

- (Optional) Add Notes with any custom requirements or additional information. Users you tag will receive the note as a notification in the Admin Portal and in Sellercloud’s Delta interface.

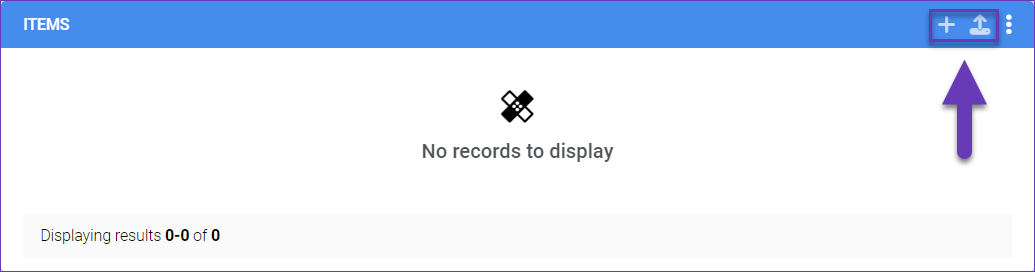

- In the Items panel, you’ll find two methods to add products to the Work Order:

- By searching and adding specific products

- Via a Bulk Import

Add Items

Next, proceed to add kits to the assembly task. You can do that either individually or in bulk.

Individually

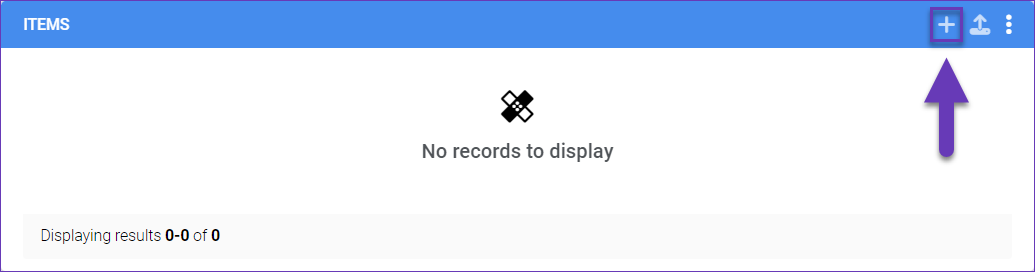

- In the Items panel, click on the + icon.

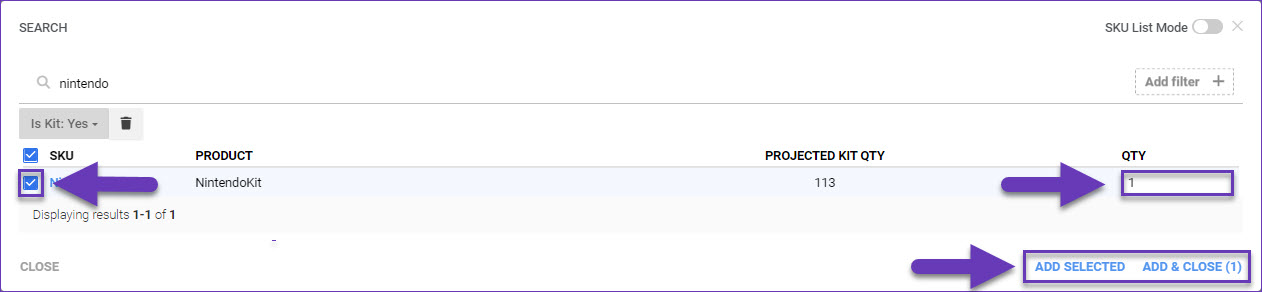

- For efficient search results, the Is Kit filter is enabled by default for all Work Orders of type Kit Assembly. Search for the required kits by entering their SKUs, separated by commas.

- Select one or multiple products from your search results by checking the respective checkbox and populating the required quantity in the Qty field.

- Click Add Selected and proceed with the selection or click Add Selected and Close, if done.

- The chosen products will appear in the Items panel.

In Bulk

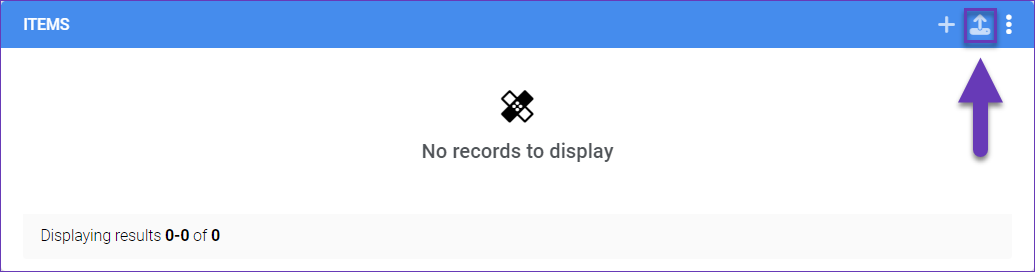

- In the Items panel, click on the Bulk Import icon.

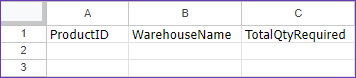

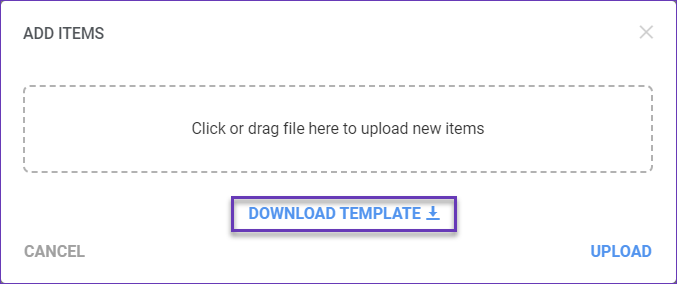

- Click Download Template and select a location to save the file.

- Open and populate the Excel file:

- ProductID – Add the SKU of the kit that you intend to assemble.

- WarehouseName – Enter the name of the warehouse, for which the work order applies.

- TotalQtyRequired – Insert the number of items to add.

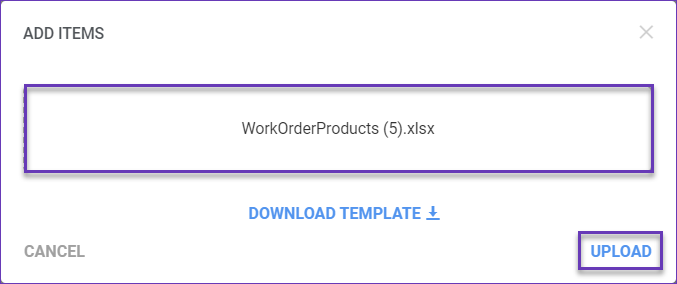

- Once all required products have been added, save the file and return to the Bulk Upload prompt.

- Add the saved file and click Upload and the products will appear in the Items panel.

Manage Work Orders

In this section, you will learn how to manage your existing work orders in the Skustack Admin. In addition to creating new work orders, you can also:

- Search – By work order number, type, and status.

- Edit Items – Add new products to the work order or delete existing ones.

- Delete – Permanently delete work orders.

- Close – Move Completed work orders into a Closed status.

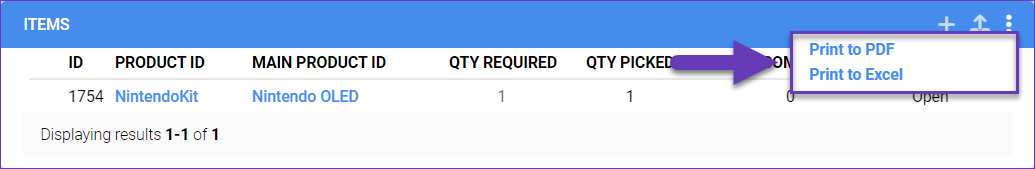

- Export – To either Excel or PDF format.

Search Work Orders

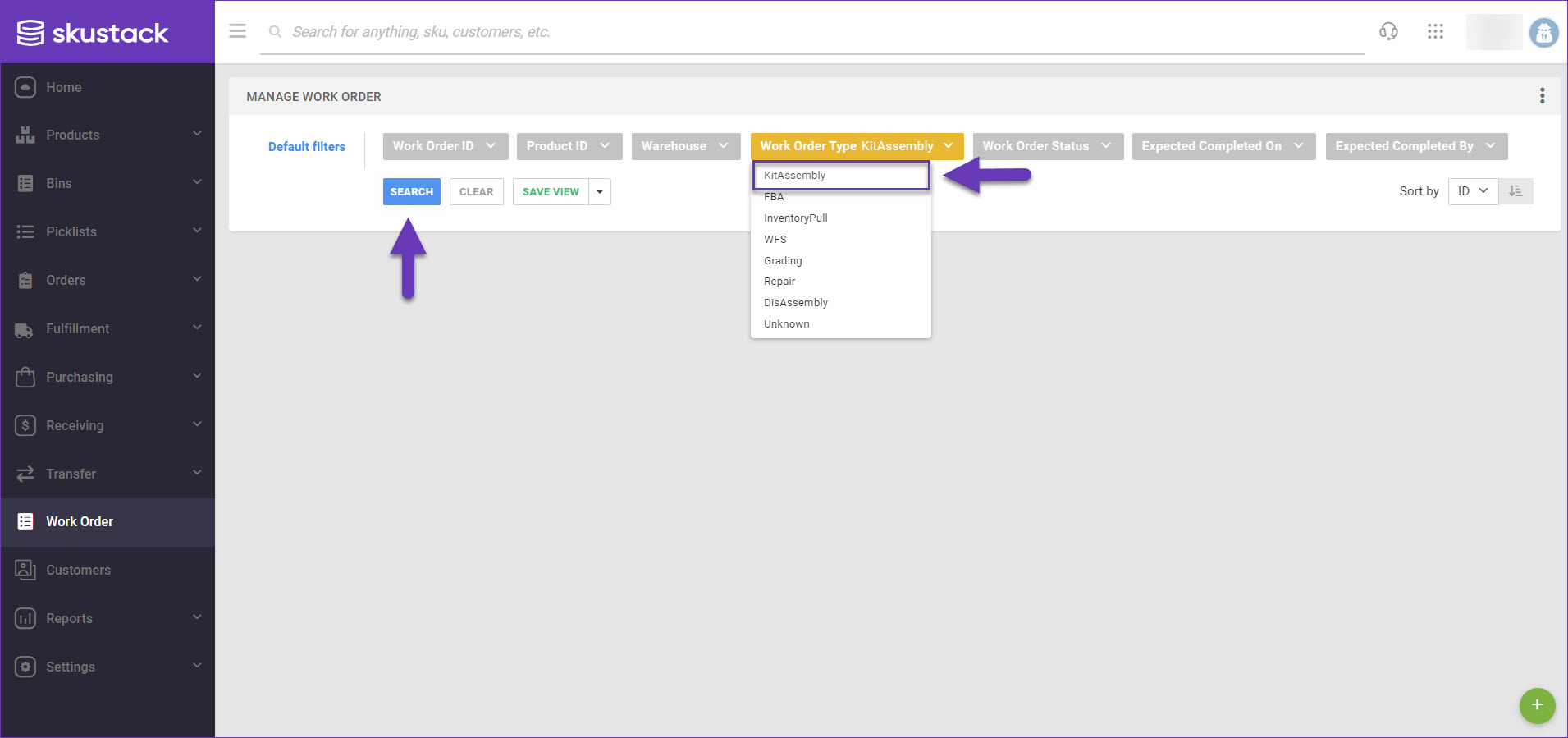

To search for existing Kit Assembly tasks in the Skustack Admin:

- Navigate to the Work Order menu.

- Configure your Default filters to ensure that the results display exactly what you need and select Kit Assembly as the Work Order Type.

- Click Search. Each filter you apply gets highlighted. If a filter is gray or not displayed at all, it’s not active.

- To manage the columns in the grid, click the three dots icon on the top right and select Customize Columns. You can:

- Reorder columns by dragging them up or down in the list;

- Hide columns by clicking the Trash icons;

- Add columns by clicking Add column.

- To arrange the data in a different order, use the Sort by menu.

- To save your filtering and sorting options, click Save view, enter a Name, and click Save.

Edit Items

To edit items on a work order, follow these steps:

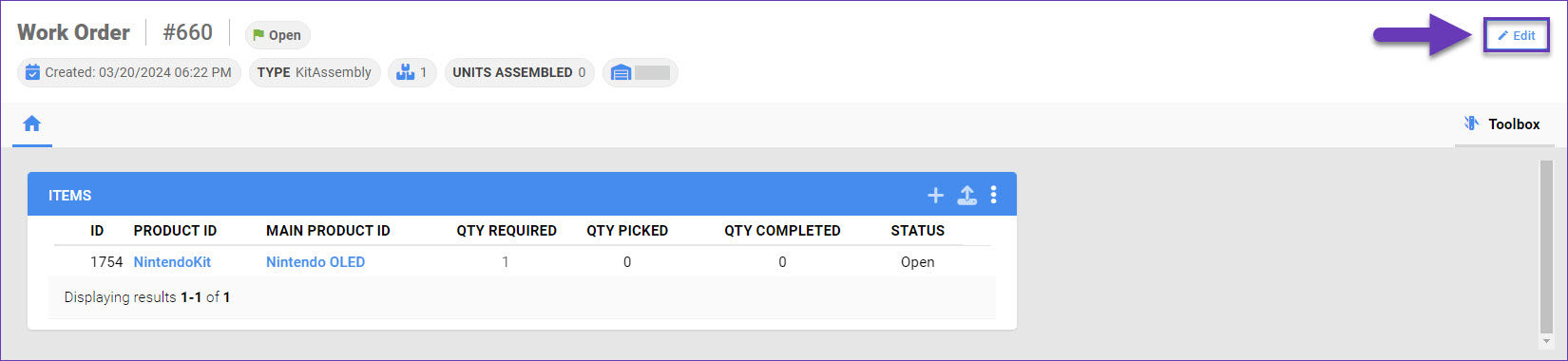

- Open your desired work order.

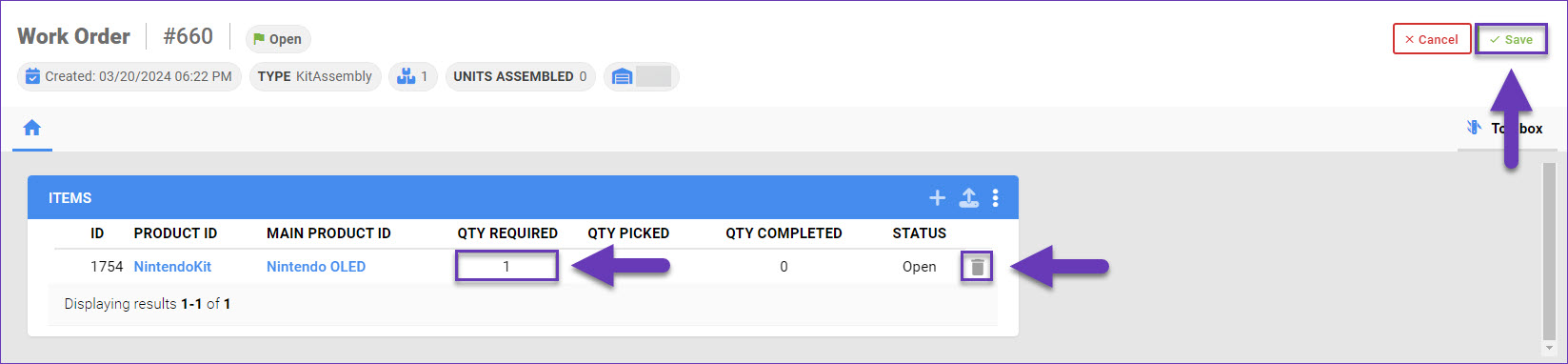

- Click Edit.

- In the Items panel, you can update the Qty Required or use the trash can icon to delete an item.

- Once done, click Save.

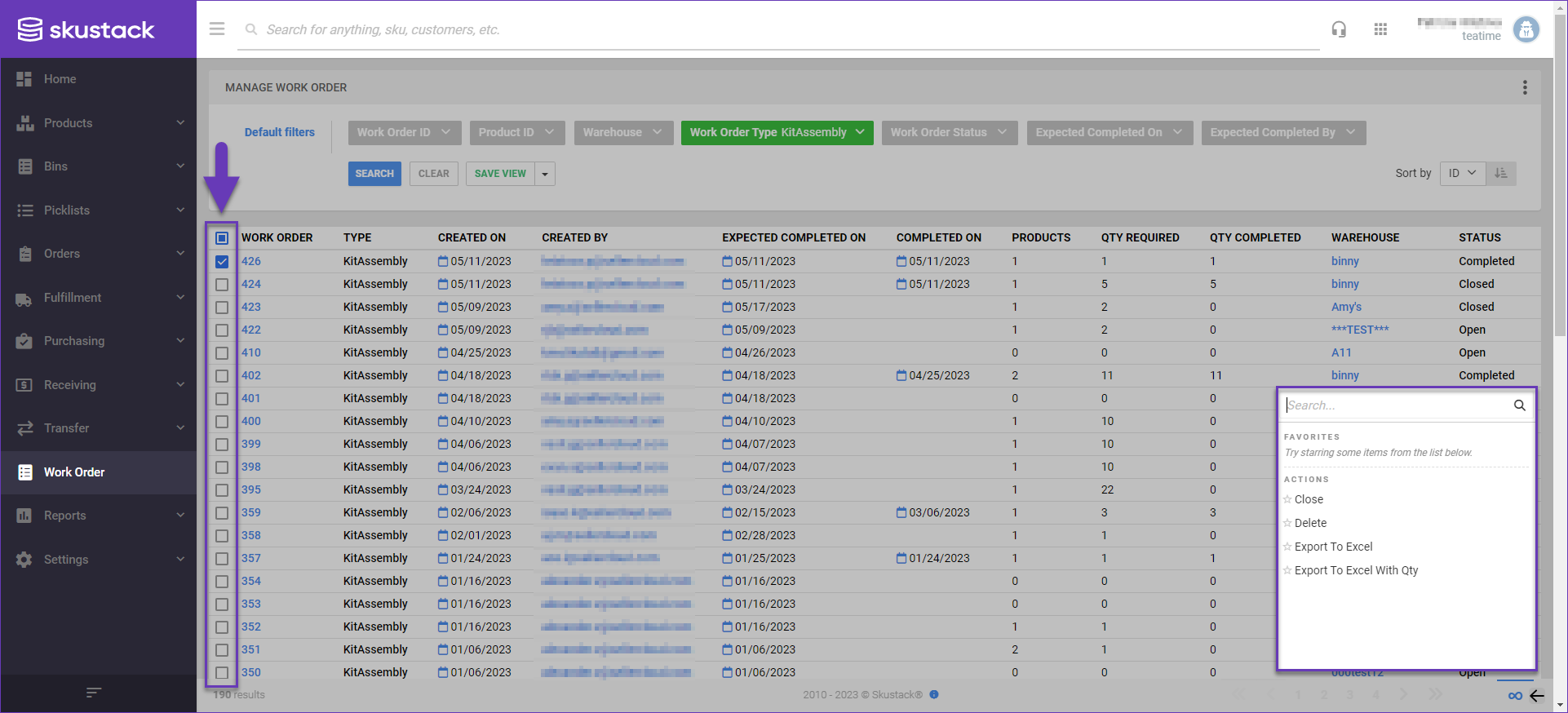

Close or Delete Work Orders

To close or delete work orders, follow these steps:

- Navigate to the Work Order grid.

- Search and select your desired work orders.

- Access the Actions menu.

- Click Close to update the status to Closed or Delete* to delete work orders.

Export Work Orders

Generating a document that includes the ID and item details of the work order can help ensure that the instructions are clear and easy to read. This can simplify the process of distributing the task to Skustack users within your warehouse. Work orders can be exported either in a PDF or Excel format. Note that exporting in a PDF format can only be done through the three dots menu on the Items panel of an individual work order.

Related Settings

| SETTING | DESCRIPTION |

| Validate serial globally | Client setting. Enables serial number validation in Skustack. Learn more about serial number validation and relevant client settings here. |

| Require Component Serial Scan If Necessary | Skustack’s Warehouse Management setting. When enabled, will force the user to scan serials for components that are set to require serial scan. |

| Scan To Assemble | Skustack’s Warehouse Management setting. When enabled, will force the user to scan kit components to assemble them. |

| Auto Print Kit Labels | Skustack’s Warehouse Management setting. When enabled, kit labels will be printed automatically upon assembly. |

| Auto Close After Fully Assembled | Skustack’s Warehouse Management setting. When enabled, the work order status will be automatically updated to Completed. |

| Allow Unlock Work Order | Skustack’s Warehouse Management setting. When enabled, this setting allows you to edit/add products to Work Orders. |

| Auto populate progress quantity when bin is selected | Skustack’s Warehouse Management setting. When a bin is selected, the Pick Qty field will automatically be set to the total quantity available in that bin, up to the quantity required. |