Overview

Cross-docking refers to the process of transferring products from inbound trucks to outbound trucks, with little or no time spent in storage. In other words, cross docking involves unloading materials from an incoming PO and then immediately loading them for shipping, without first putting them into storage.

This process is designed to minimize the time and cost associated with storage and to streamline the distribution process. Cross-docking is especially helpful for handling backorders and is often used when products must be moved quickly and efficiently in order to meet customer demand. It can also help reduce inventory costs and improve overall supply chain efficiency.

Pick Backorder Items

To pick backorder products from the Receive PO module, follow the steps below:

- Navigate to Receiving > Receive PO.

- Select your desired Search Mode > tap Go.

In the Search All mode you can filter by the Received status of the PO’s (e.g Zero, Partial, etc).

- Tap on the desired PO.

- Products on that PO will load.

- If there is cross-dock quantity on the PO item, a cross-dock icon will display on that row. Long-press on the icon to see the cross-dock details.

- Tap the picklist icon.

- Enter a specific picklist number or browse your existing lists.

- Tap Save to assign the picklist to the PO. A success message and green checkmark icon will indicate that the backorder picklist is set.

If multiple orders are linked to the same PO and different picklists are generated for them, you may have to repeat the process for each Picklist ID. Picklists must be processed one at a time.

If multiple orders are linked to the same PO and different picklists are generated for them, you may have to repeat the process for each Picklist ID. Picklists must be processed one at a time. - Scan in the units or enter the received quantity manually.

- Select a receiving bin and tap Receive.

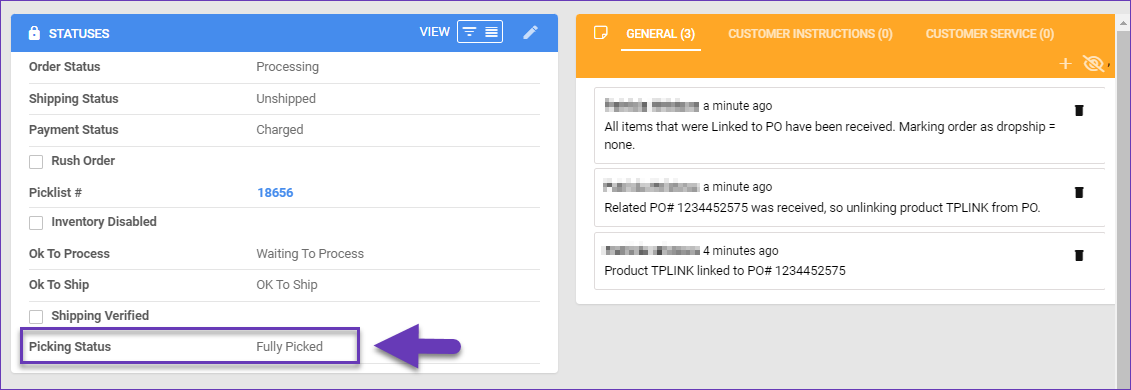

- The product’s picked status will reflect on the order immediately.